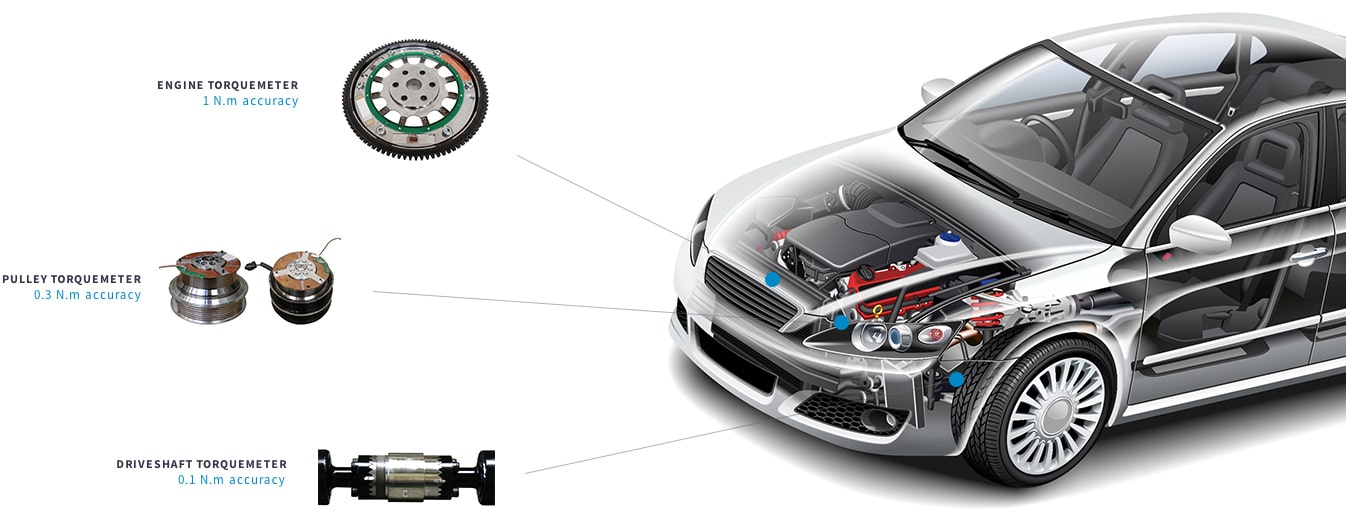

High accuracy in-vehicle measurement

Designed for vehicle real use applications

GREENMOT has developed various torque measurement systems providing high dynamic accuracy in the “in-vehicle” real use. Sensitive parts of these customized sensors are internally designed and validated to be less sensitive to external perturbations like temperature, misalignment, or Coriolis effects in real use. They adapt perfectly to the parts concerned: flywheel, drive shaft or pulley. Thus, they allow you to collect a set of relevant data for the development of your vehicle.

THE MEASUREMENT TOOLS

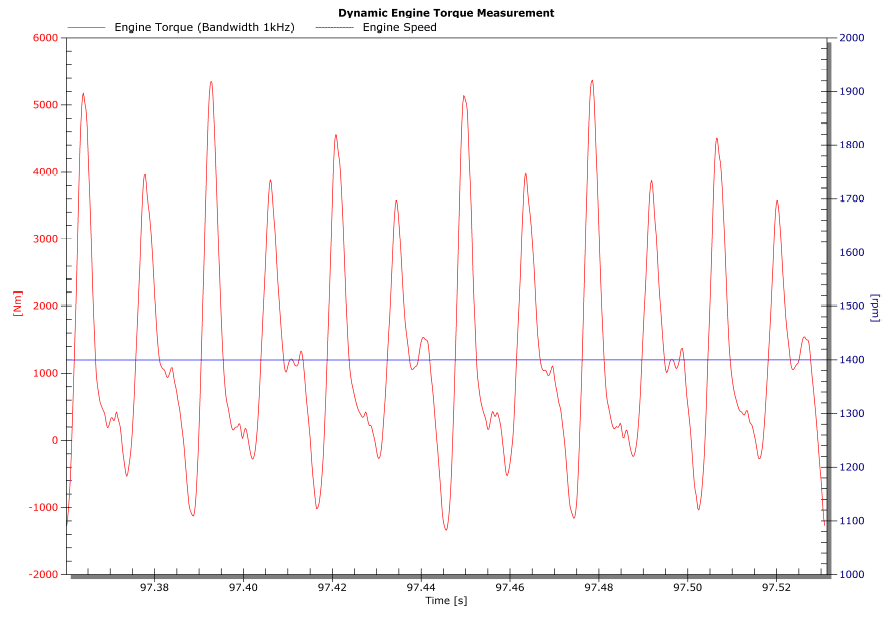

Engine torque measurement system (Flywheel / Flexplate)

Technical specifications

| Type of sensor | Strain gauges – HF Telemetry Integrated in the original design |

| Torque capacity | Dependent of maximal engine torque, typically : · 0 – 500 N.m or 0 – 1 000 N.m for passengers car · Up to 10 000 N.m for industrial engine |

| Maximum speed | Dependent of the engine |

| Accuracy | 0.2 % FS in real use in-vehicle environment |

| Bandwidth | 1 kHz |

| Temperature range | -10°C to +120°C |

| supply | 10 V to 34 V |

| Output type | 0 – 10 V |

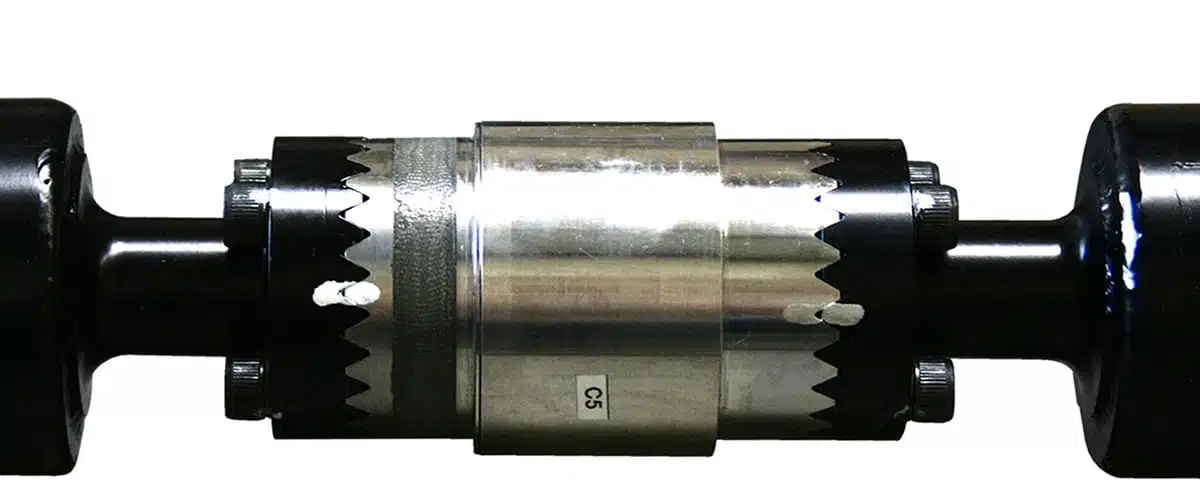

Driveshaft measurement system

Pulley measurement system

Technical specifications

| Type of sensor | Strain gauges – HF Telemetry Integrated in the original design |

| Sensor inertia | 120 kg.mm² |

| Torque capacity | 0 – 100 N.m |

| Maximum speed | 6 000 rpm |

| Accuracy | 0.3 % FS in vehicle environment |

| Bandwidth | 1 kHz |

| Temperature range | -10°C to +80°C |

| Supply | 10 V to 34 V |

| Output type | 0 – 10 V |

APPLICATIONS

Engine mapping / development – Transmission development – Hybrid powertrain development

Traction control – Energy flow mapping – Engine vehicle integration

GREENMOT maintains a policy of continuous research and development and specifications are subject to optimization without notice.