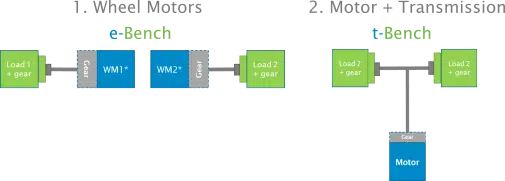

Why invest in an e-bench? Developing new quality engineering products consistently and having a strong place in your niche is one of the most powerful yet challenging activities. Product designers face various challenges during the development cycle, some of them are technical, others are related to external factors.

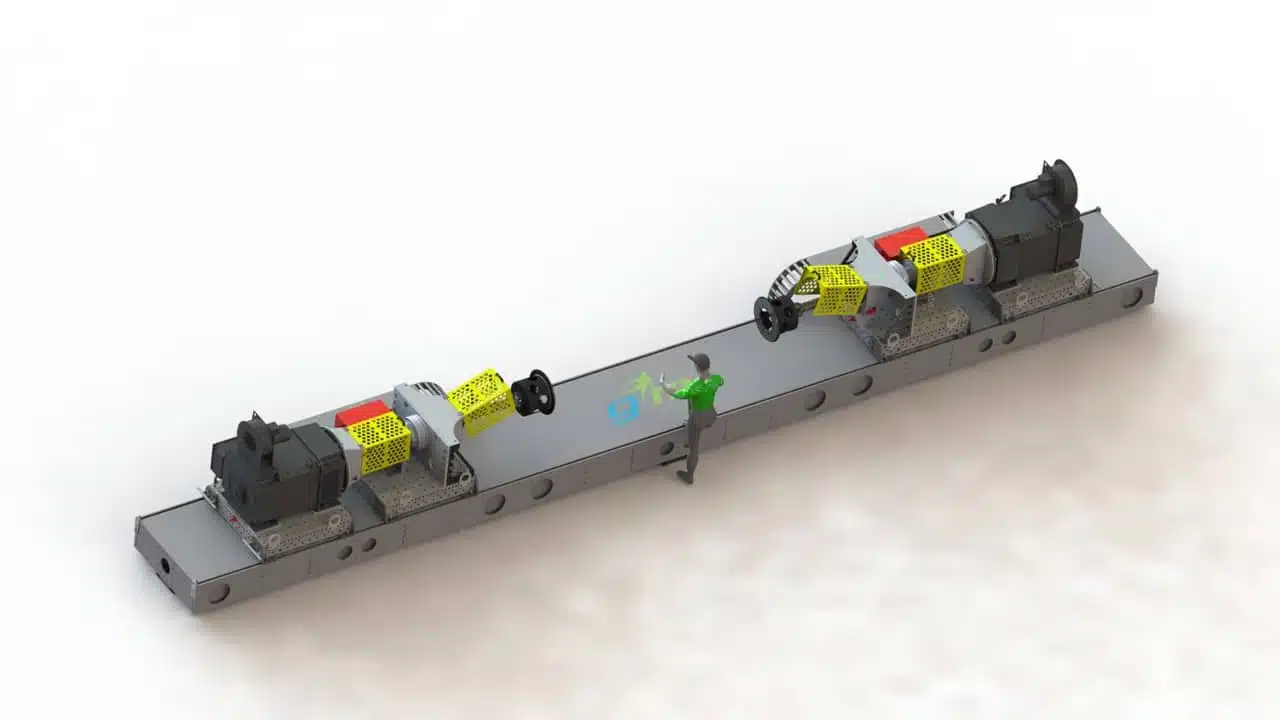

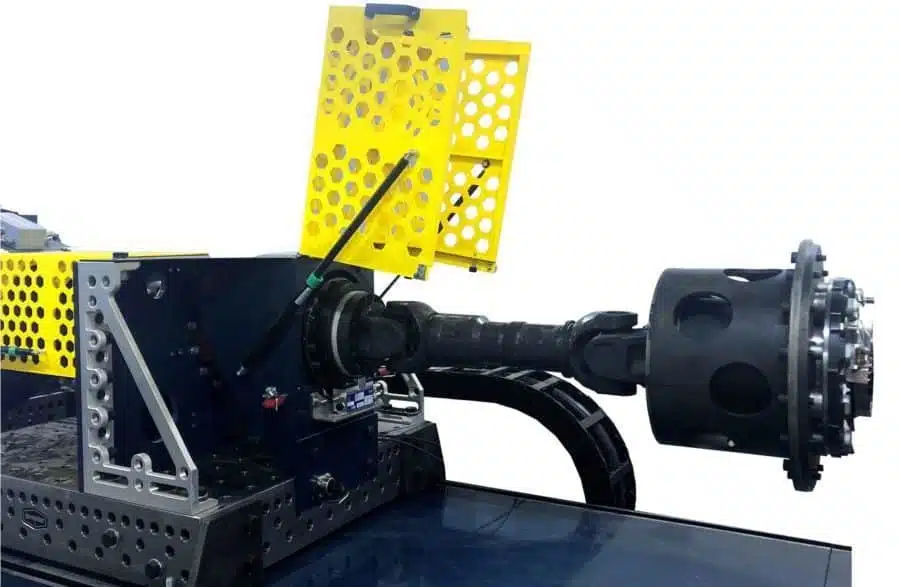

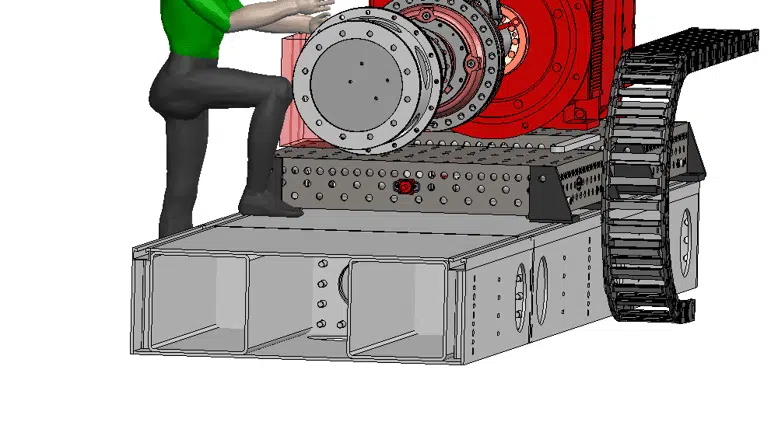

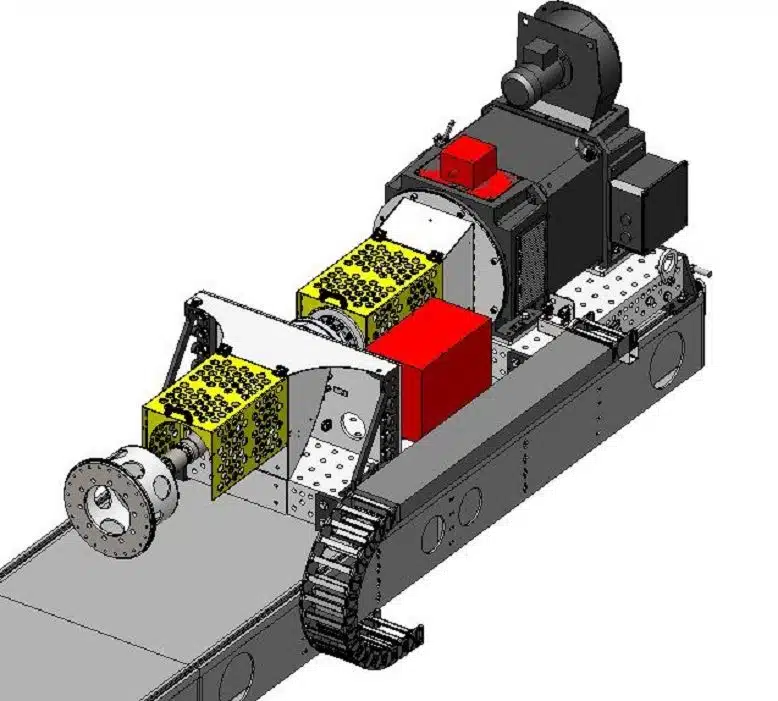

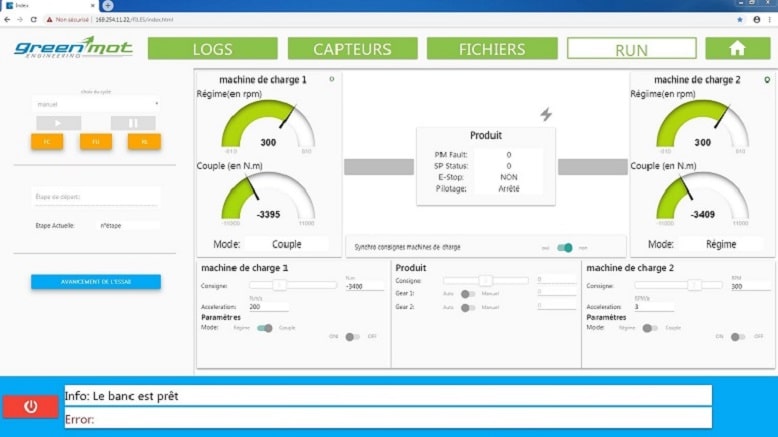

Thanks its expertise in the test bench management, GREENMOT is the ideal partner to help you define your needs and provide a bench dedicated to these specific needs.