Global & Custom packages

In the current context of vehicle powertrain diversification, our testing resources and expertise are made available to your R&D teams and offices to carry out comparative performance studies. These vehicle benchmark studies combine experimental data and strategy analysis to identify the main technical drivers behind carmaker choices on architecture, technology or strategy.

The study is made of two phases.

1. The first part will address the following critical measurements and their implementation – without any interference with car management system :

- Mechanical Power: Driveshaft, Engine and Electric Motor (specific torque sensor)

- Electric Power (DC & AC): Battery and HF Inverter Output

- Emissions

- Cockpit and Powertrain thermal management system (pressure, flow, temperatures)

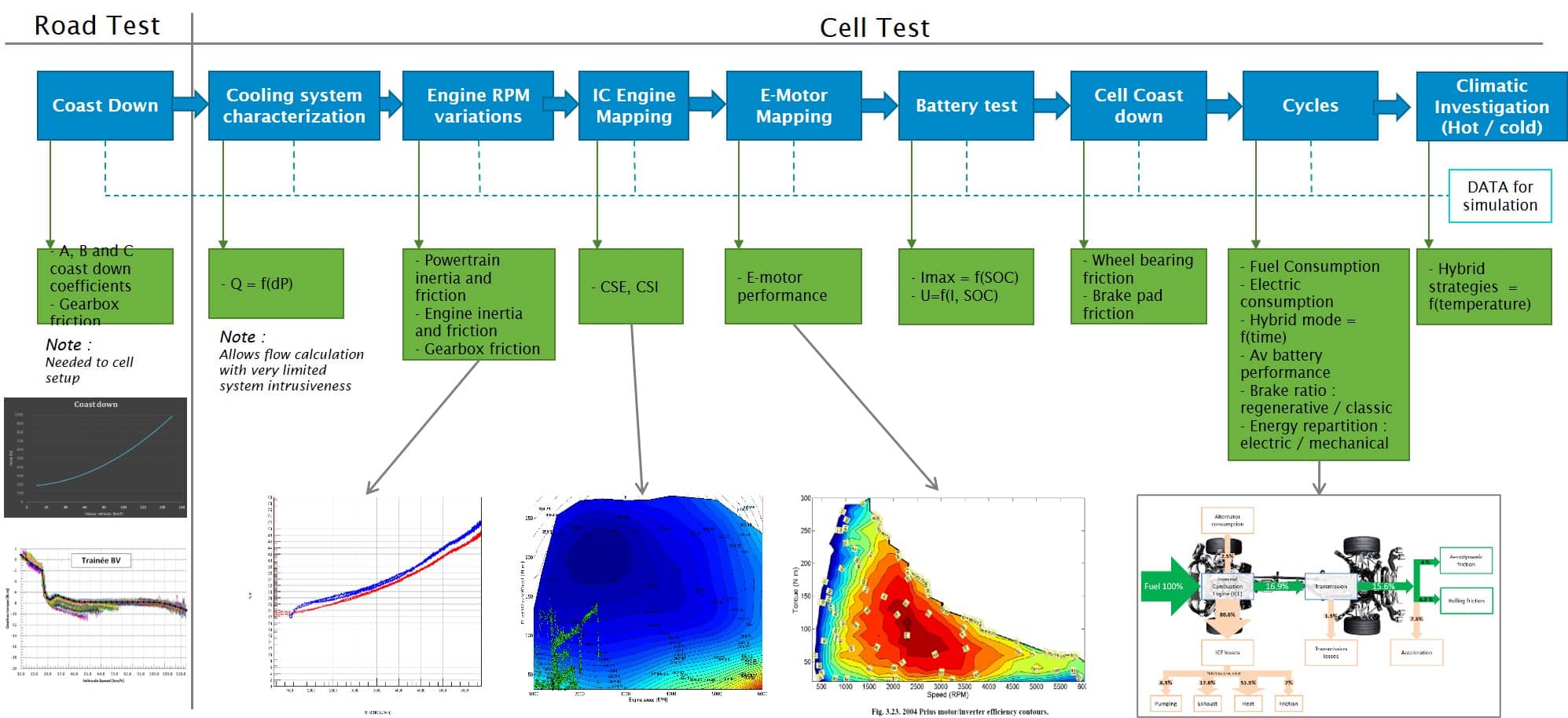

2. Secondly, the test program combines both road and test benches sessions:

- Coast down

- Cycle (-10C 20C 45C): NEDC, WLTC, RDE and replays in hub dyno test cell

- Specific tests for characterisation or energy management strategy investigation : Mappings, Braking Recovery, Acceleration (0-100,80-120), Battery charging at different temperature, etc

Vehicles Benchmark : the test programs

DATA PACKAGE AVAILABLE

Raw data and maps are available.

Several data packages are available on e-powertrain, HVAC performance, thermal management system efficiency. Customized reports can also be provided upon request. Contact us for more information.

> Global PWT efficiency mapping

> Individual component efficiency mapping (inverter, motor, transmission)

> Derating points identification

> Regenerative braking performance

> Analysis with different ambiant t° & battery SOC

> Complete thermal and energy analyses of the cooling/heating system

> Coolant flow, temperature, energy consumption of compressor/heater

> HVAC & Interior comfort measurements on dynamic driving cycles

> Full mapping characterization in terms of energy consumption and emissions. Complete thermal balance in real driving conditions (RDE type)

> ICE efficiency mapping, electrical motor efficiency mapping, combustion analyses, fuel consumption, emission analyses

> Dynamic hybrid powersplit strategy analysis on standard / custom cycles

> EGR susbsystem analysis

> Global energy analysis, thermal management of components

> Engine lubrication circuit management understanding & oil aging test

Methodology & Instrumentation

GREENMOT has developed an “in situ” measurement operating in a real environment. Our knowledge and experience in the field of metrology allow us to implement customized sensors meeting your specific measurement needs : pollutant emissions, electric motor phase, engine torque, etc.

Thanks to our automotive expert team, the vehicles are dismantled, equipped with the sensors and mounted back, at our French workshop. The instrumentation is therefor adapted to each particular project and the project is taken care of by a dedicated engineer.

Our methodologies and self-developed tools allow you to process the large volume of data generated during a global vehicle test campaign. The results generated provides you with an overwiew of the market caracteristics, in order to help you working on improved functions and systems.

VEHICLE BENCHMARK PROCESS

Global vehicle approach : open roads and test benches tests

“In situ” instrumentation and repeatability of the test conditions

Self-developed tools and methodologies to process a large volume of data generated

Vehicle Benchmark Brochure