An innovative test center, GREENMOT offers you turnkey vehicle testing services. Drawing on the skills of our experts and our internal testing resources, we are a partner to tackle current challenges. This particularly concerns the reduction of vehicle consumption and emissions, and the hybridization of powertrains.

We support you on the following topics

✅ Preparing new RDE regulation with vehicle testing facilities providing large operating ranges in terms of engine RPM / load / temperature.

✅ Accurate quantifying fuel/energy savings provided by eco-innovations

✅ Hybride control strategy optimization

✅ New calibration programs reducing vehicle development time

TEST CENTER | METHODOLOGY | INSTRUMENTATION | POST-PROCESSING

TEST CENTER

Methodology

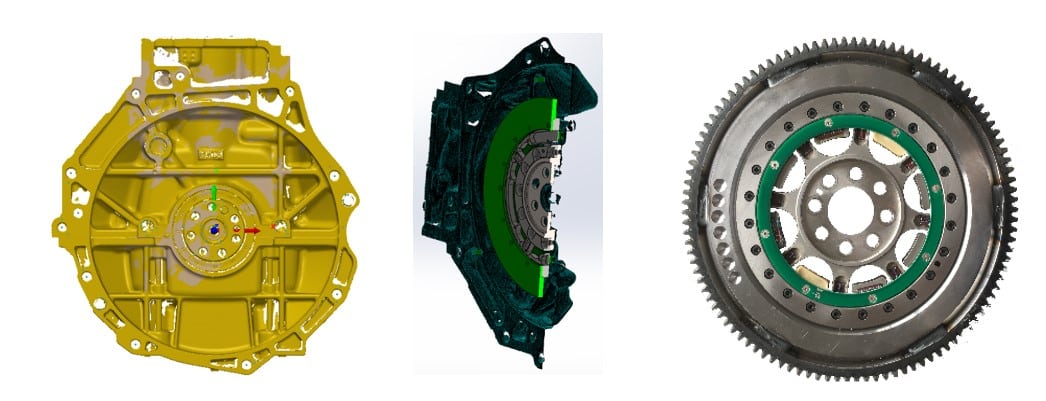

Definition – Specific design – Calibration – Installation

GREENMOT uses an “in situ” measurement approach in the operating environment. Our expertise and methodology allow us to understand measurement environment and to reduce intrusiveness of this measurement.

Testing plan – Tests campaign – Test benches availability

GREENMOT has developed innovative testing solutions optimized for their repeatability and their performance level (Automative climatic test cell – High power climatic test cell – Component test benches)

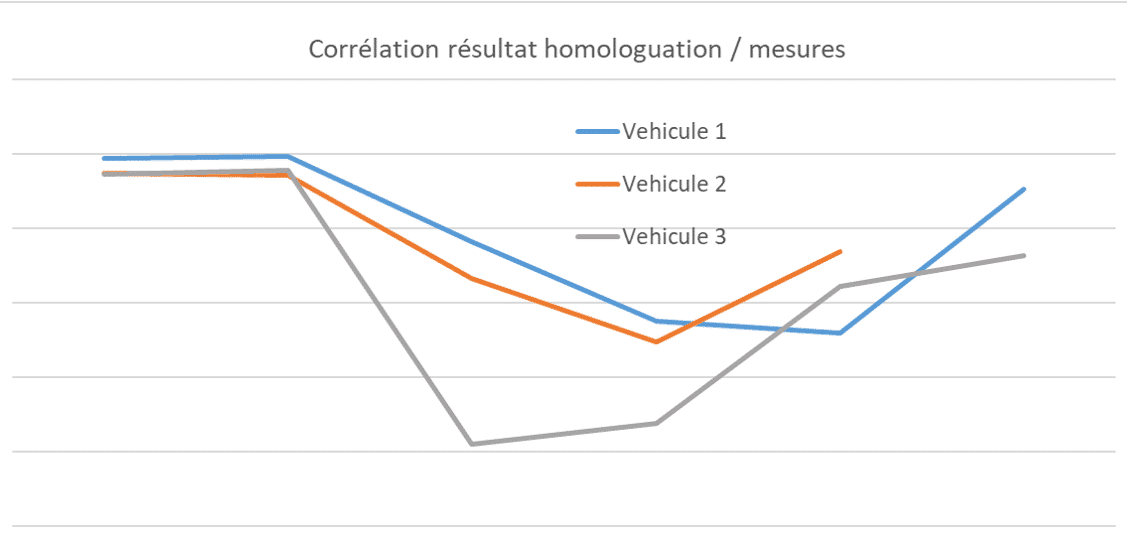

Data validation – Automatic formatting – Analysis

Global vehicle test campaigns generate important volume of data to be processed, GREENMOT has developed methodologies and automatic tools for data validation and data formatting.

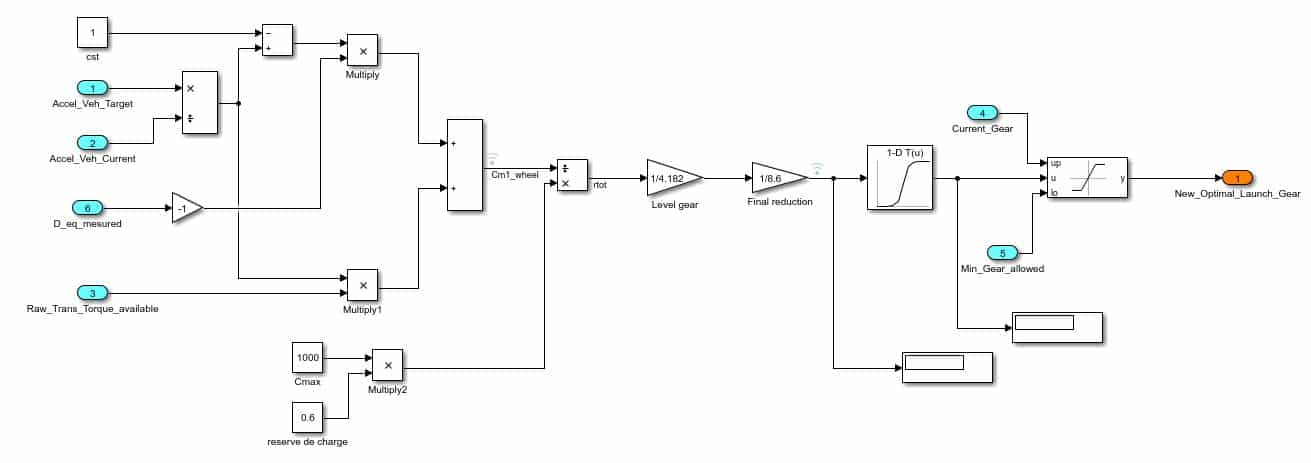

Simulation

GREENMOT uses Amesim software, Matlab or any customer dedicated software.

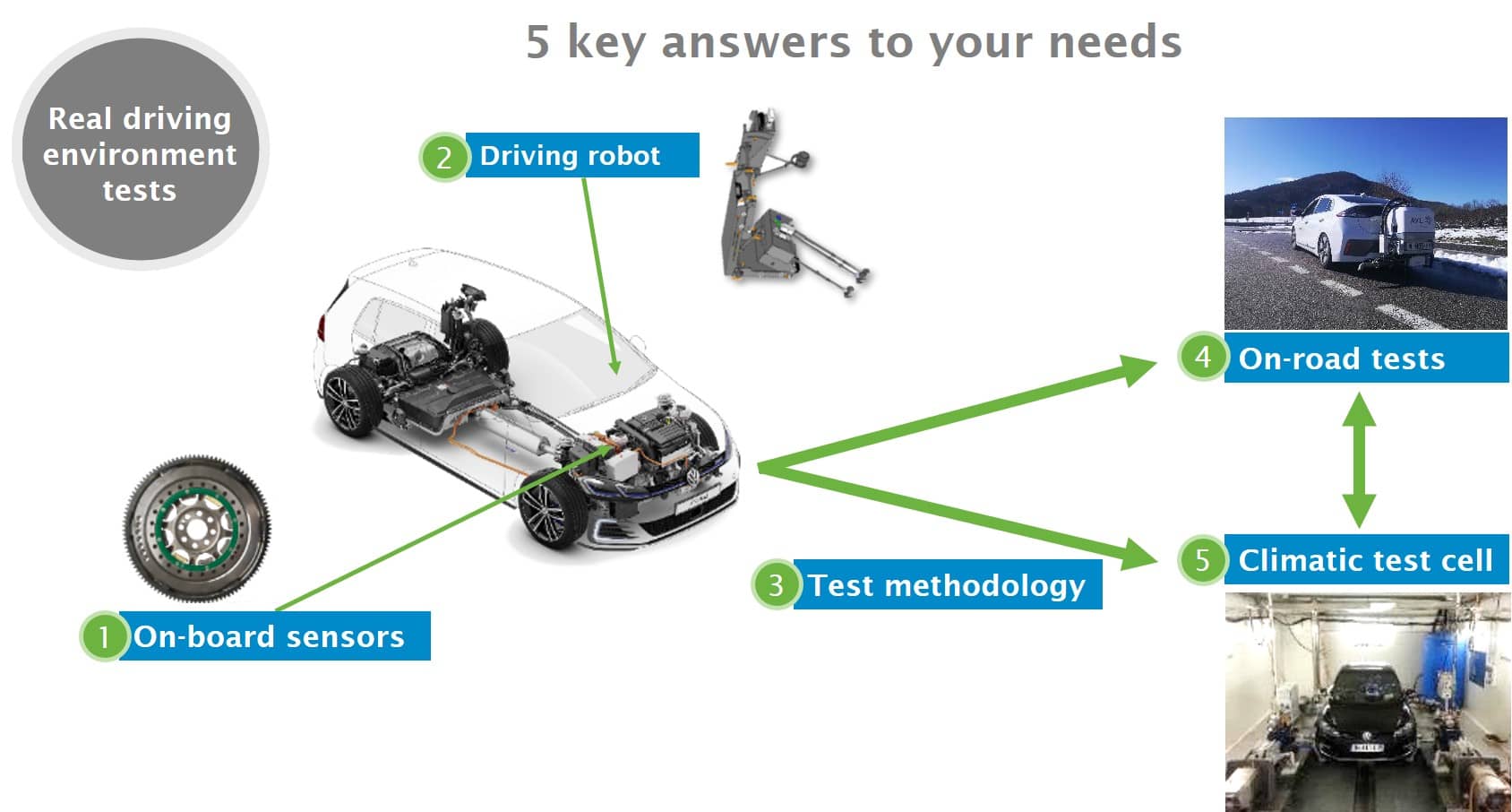

How to develop your vehicle while mastering the testing service environment?

For acheiving the highest provision of services, GREENMOT has chosen the following innovative approach : “Put the component benches into the vehicle rather than the vehicle components in the test bench“. Indeed, the physical value measurement is only significant if :

- It is measured without disrupting the system,

- It is realized without environment changes,

- It is realized in real-use and realistic conditions,

- The physical measurement point is under control.

Data collection & post-treatment

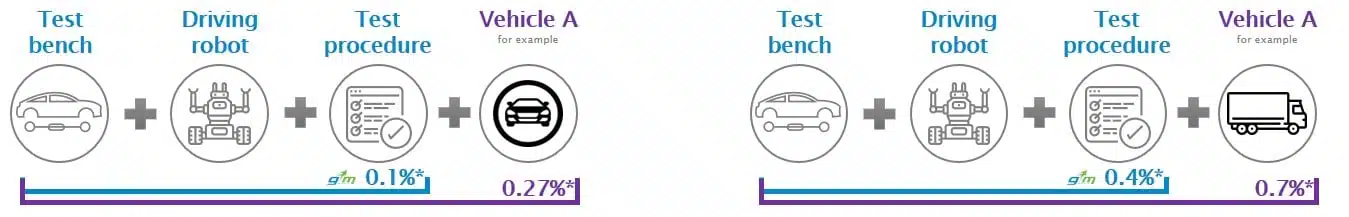

Thanks to its methodolgy and its specifically designed tools, GREENMOT is able to offer you a very high repatability between several tests on the same driving cycle.

* with CI95 // test proven

Instrumentation capabilities

Specific Sensors

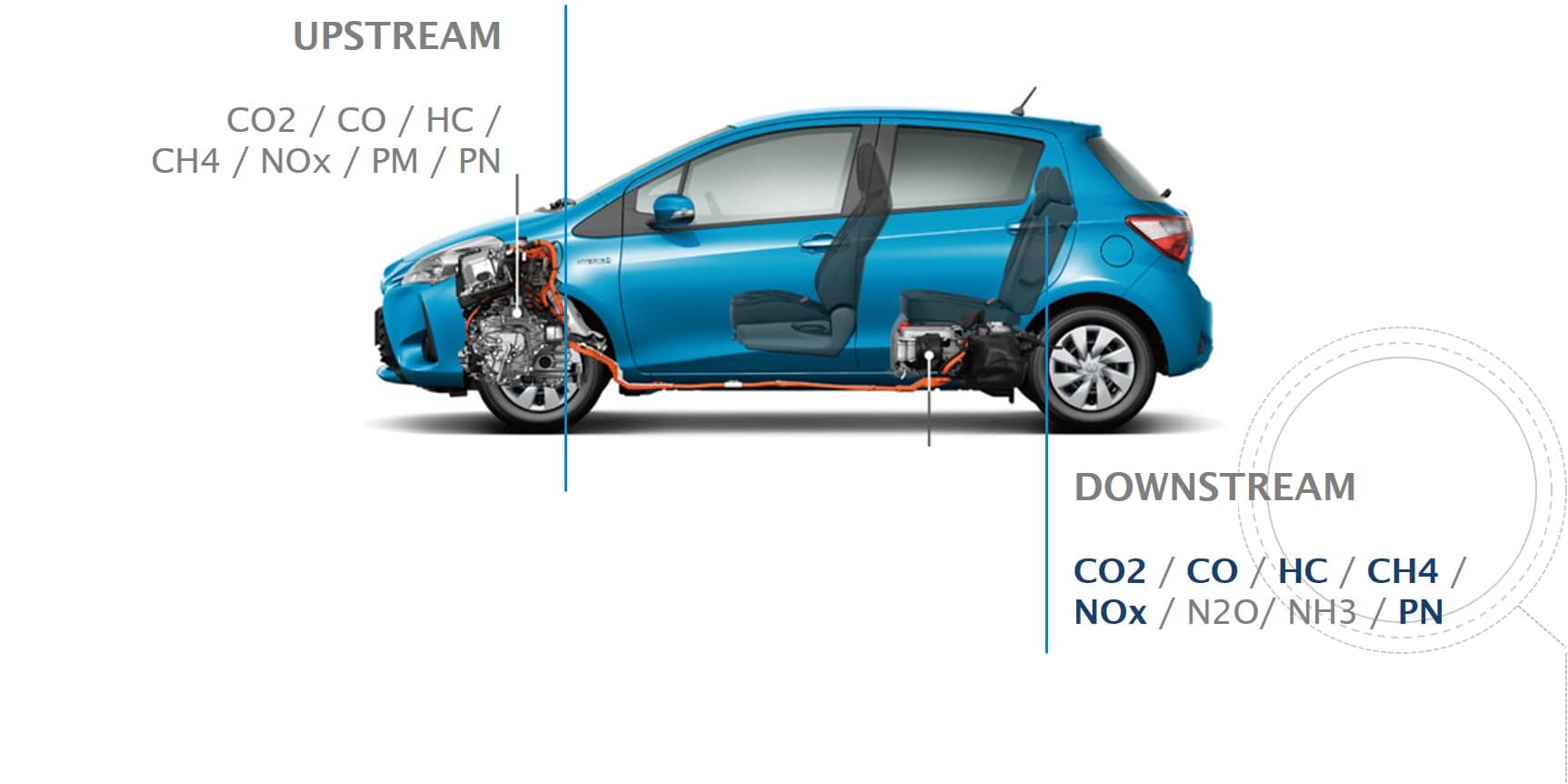

Consumption & Pollutant emissions measurements

Portable Emissions Measurements System – PEMS

This on-board measurement tool is installed on the vehicle and analyzes the flow of exhaust gases in real use. In order to analyze this flow, the vehicle travels on open road according to a specific driving route, which combines urban, peri-urban and motorway roads. Our geographical location, close to the Alps, allows us to collect data under specific conditions, in particular information related to mountain driving.

Applications

BENCHMARK | HEAVY DUTY TRUCKS | BUSES & COACHES | TRACTORS | MILITARY VEHICLES | OILS & FUELS | DRIVING CYCLES

VEHICLE BENCHMARKING

- Stability and extreme repeatability of test environment

- Global physical instrumentation that do not require any confidential OEM / suppliers information (like OBD,…)

- Global vehicle approach allowing to acquire maximum data in one single test campaign environment.

Find out on our Benchmark strategy and methodology

HEAVY DUTY TRUCKS

Truck test campaigns in extrem climatic conditions

WHTC, WHVC, 60NERV or other driving cycles

BUSES & COACHES

Bus test campaigns on 12m, 18m, articulated and/or double-deck buses

SORT / E-SORT driving cycles or others, as requested.

AGRICULTURAL & FARMING VEHICLES

Already provided tests such as A/C performance validation & transmission load

MILITARY VEHICLES / DEFENCE

Military qualification on warm / cold climate

NATO-STANAG standard / AECTP 300

FUELS, OILS & LUBRICANTS

Case study on consumption & pollutant emissions